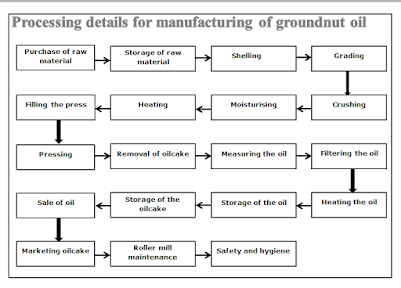

Ground Nut Oil Manufacturing Process with Flow Chart | How to do manufacturing of groundnut oil

This below given is the flow chart of the manufacturing process of groundnut oil.

Step-1:

- First of all we have to purchase the raw material from any organization or from processing industry.

- After completion Step no 1, we have to store the raw material in a stock room where there should be no sunlight falls in that place

Step-3:

- Next processing is shelling, it is nothing but removing of the waste from the groundnuts.

Step-4:

- In this step we have to do grading, it is nothing but we have to remove damaged groundnuts from the raw materials.

Step-5:

- After completion of the grading process we have to go for crushing in this we have to crush the groundnut seeds.

- In this step we have to do moisturing it, the main use of this is to remove any moisture from the groundnut seeds.

Sep-7:

- In this step we have to heat the groundnut seed in a combustion chamber, without presence of air.

- Heating should be continued for some time as per the schedule i.e. maximumly 2 to 4 hours

Step-8:

- We have to pour the residue that came out after heating in a pressing machines,

- This pressing machine should be made up of steel, iron, aluminum, fiber, wood etc...

Step-9:

- After that we have to on the machine and the pressing of the groundnut seeds will starts and after some time the oil comes out from the machine.

- We have to keep a bucket at the side of the machine where the oil is coming out.

Step-10:

- After completion of pressing we should remove the oil cakes, which forms sue to pressing.

- These cakes can be further used as a food to animals like Buffaloes, cows..

Step-11:

- After step-9, we have to measure the oil which came from the pressing machine and that should kept in a separate clean place for further process.

Step-12:

- After measuring the oil we have to filter it to remove all impurities from it.

- Top class filters should be used for filtering the oil.

- Maximumly we have to do twice or thrice filtration of the oil to remove total impurities from the oil.

Step-13:

- After doing the filtration process we have to heat that filtered oil for some time period, the main use of heating is to store the oil for longtime

Step-14:

- After successful heating of the oil we have store the oil with the help of oils in neat place where sunlight as well as water should not enter in to that room, in that room we have to store the oil for further process.

Step-15:

- In this step we will also store the oil cakes which came in the process of pressing and that will also be stored for further process.

Step-16:

- In this step we have to fill the oil in small container or bottles for the sale of it.

- We can also maintain the bottles i.e. one litre bottle, half litre bottles or maximum size of bottle can be used too fill the oil for selling

Step-17:

- In this step we have to sell the oilcakes to the market or to the industry to do further processing of that oil cakes.

Step-18:

- In this step wee have to clean the equipment's what we have used and we have to do maintenance of those equipment's by doing some maintain ace process.

Step-19:

- The last step is safety and hygiene of the product that we are selling, the main thing is to store it in a good place and sell the product as early as possible and make oils newly as early as possible and don't sell the old stock to those people, it is not that much safety,

- We have be very caseous while selling the oil to the customer's, if any thing happens to customers then those all blames will comes under us so be careful while selling the oils.

Step-20:

- In this step the main thing we have to do is expanding of our industry and increase the amount of product rate.

These above are some of the step involved in manufacturing of groundnut oil.